Design and production of welded impellers

for industrial’s applications

80% of our production consists of customized products, manufactured on production lines alongside standard ones. For more than 40 years, our strength has been collaborating with customers in the design and development of products that meet their application requirements..

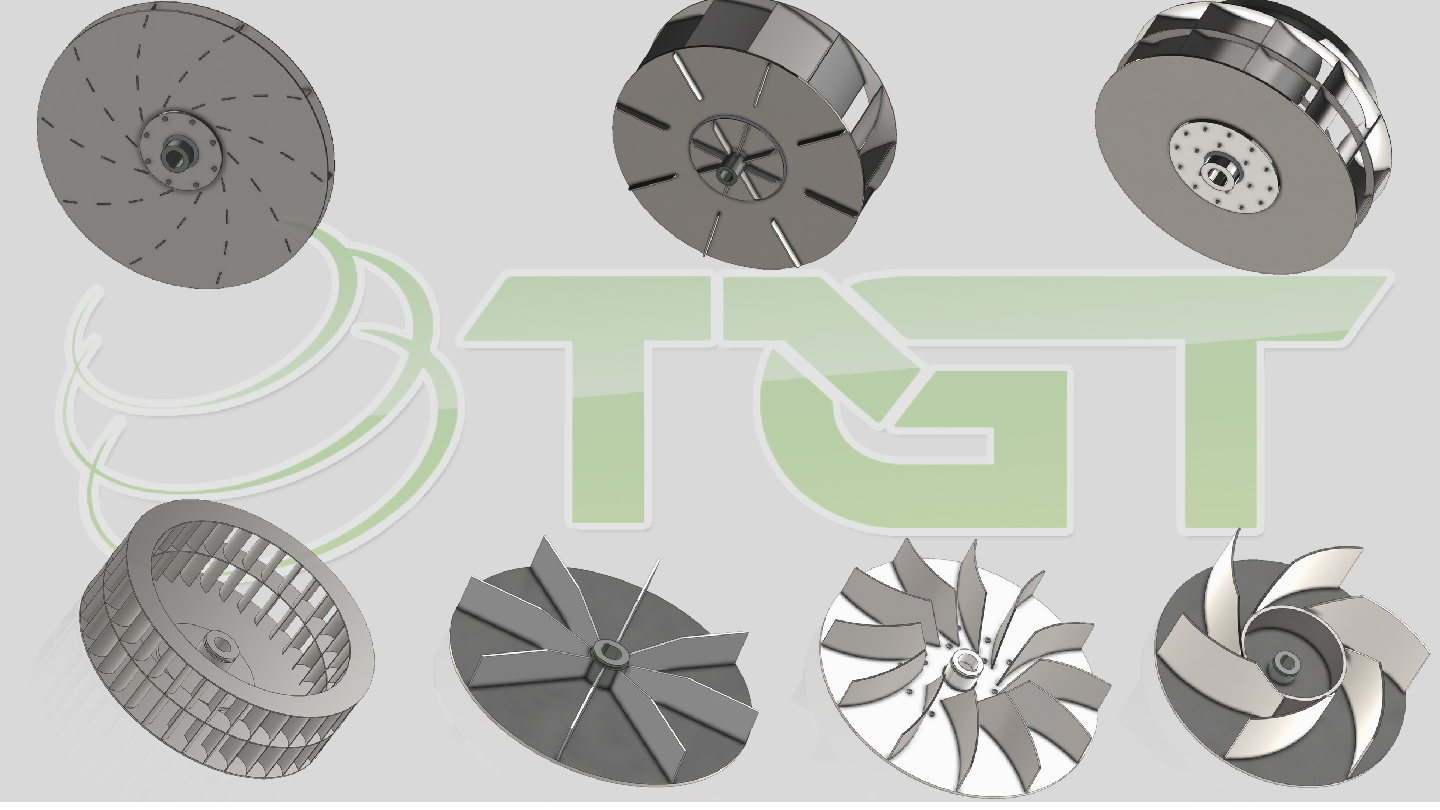

- forward-inclined blades

- backward-inclined blades

- radial-blades

- curved blades

- straight blades

- low, medium and high pressure

- low, medium and high flow rates

- 150 mm to 1450 mm diameter

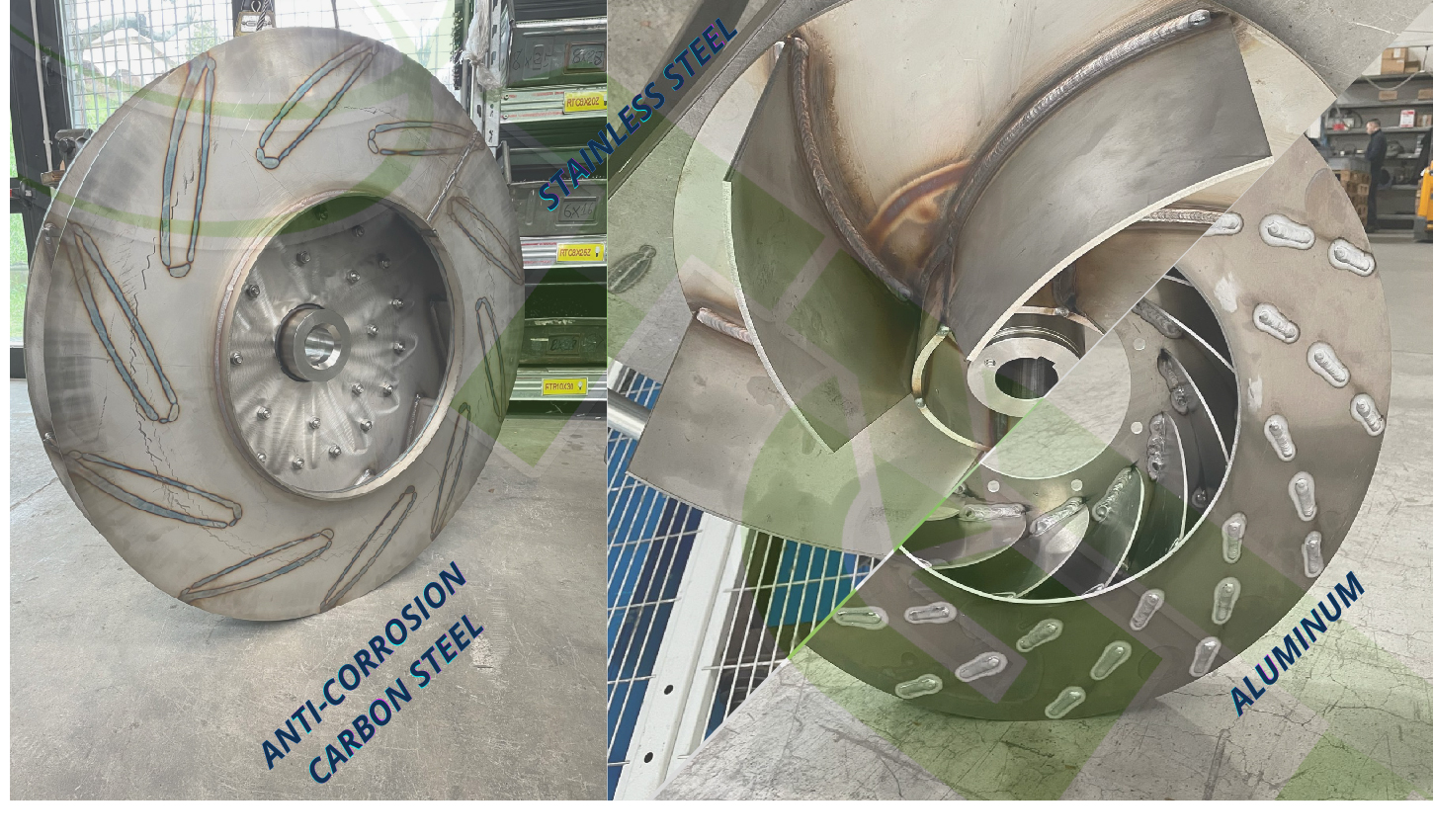

- Carbon steel - High strength carbon steel alloys

- Stainless steel

- Aluminium

- Special anti-corrosion materials such as X120Mn12, Hardox, Corten and more

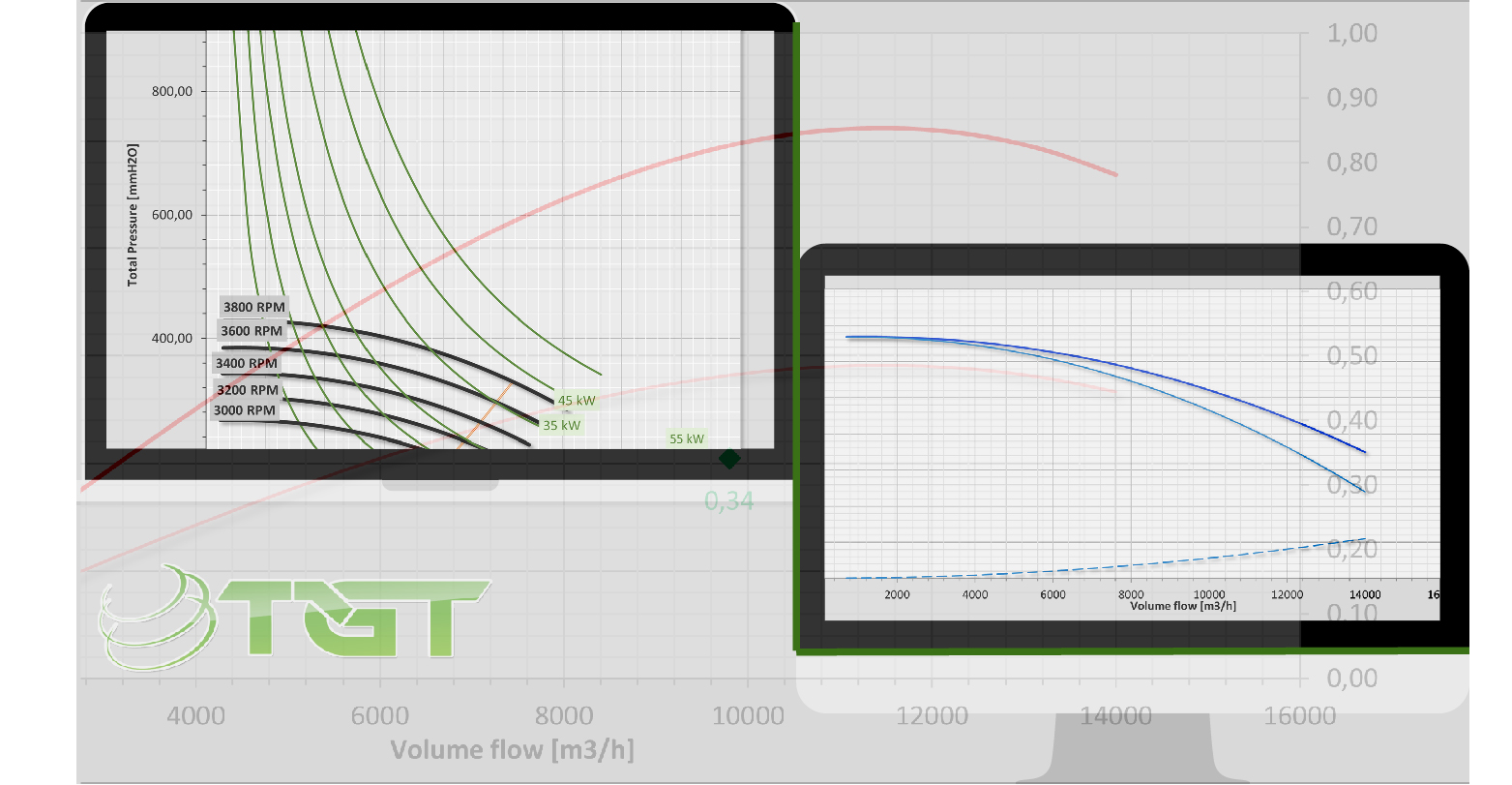

- Supply of impeller working theoretical curves

- Impeller design to performance specifications provided by the customer (pressure - flow rate - operating temperature - rotation speed - blade type)

Send us your design with your requirements for a feasibility assessment

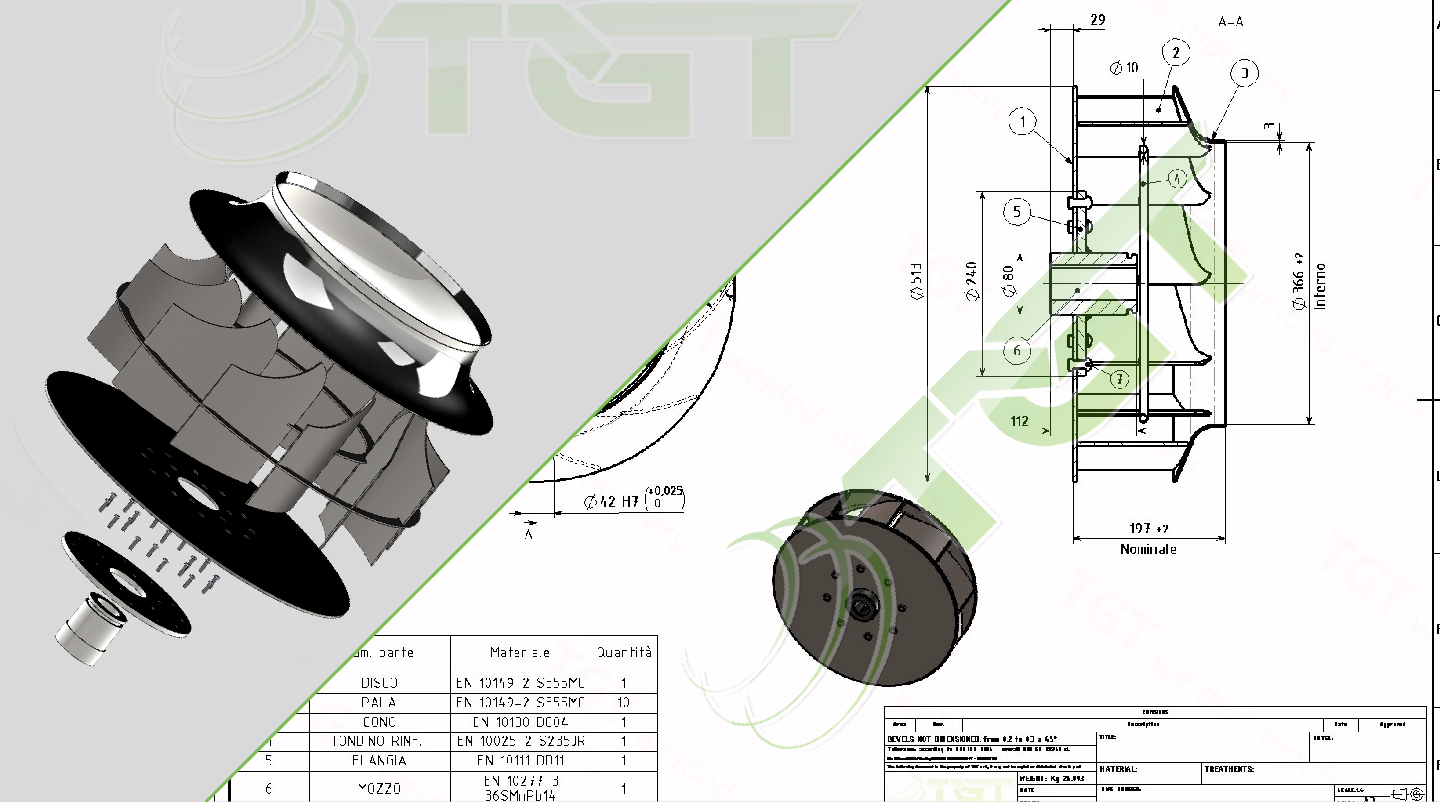

- Impeller diameter and height (dimensions A-B-C in catalogue)

- Suction diameter (dimension D in catalogue)

- Hub diameter, height, protrusion and hole (dimensions L-h-G-M in catalogue)

- Dimensions, development, inclination and number of blades

- Component thickness

- Sizing for operation at 60 Hz

- Samples

- Dimensional study and confirmation via product design and sharing in 2D and 3D format STEP - IGES - DXF

- Nothing is impossible for forward-inclined blades with a high number of blades!

-Coating oven or anti-corrosion

-White or yellow cold galvanization

-Nickel-plating

-Sandblasting

-Chemical nickel-plating

-Pickling

-Burnishing

-Anti-stick and anti-friction treatments

TGT s.r.l. - Ventole centrifughe saldate

Vicolo Collodi 1E,

Località

Rivabella - 40069 Zola Predosa (BO), Italy - Tel.: +39 051 751697 Fax: +39 051 752780 -

www.tgtsrl.com -

info@tgtsrl.com

P.I. (Eori) IT00527071203 - C.F. 00898030374 - Mecc. BO015827 - REA 233897

- Cap. Soc.

€

10.400,00 i.v.